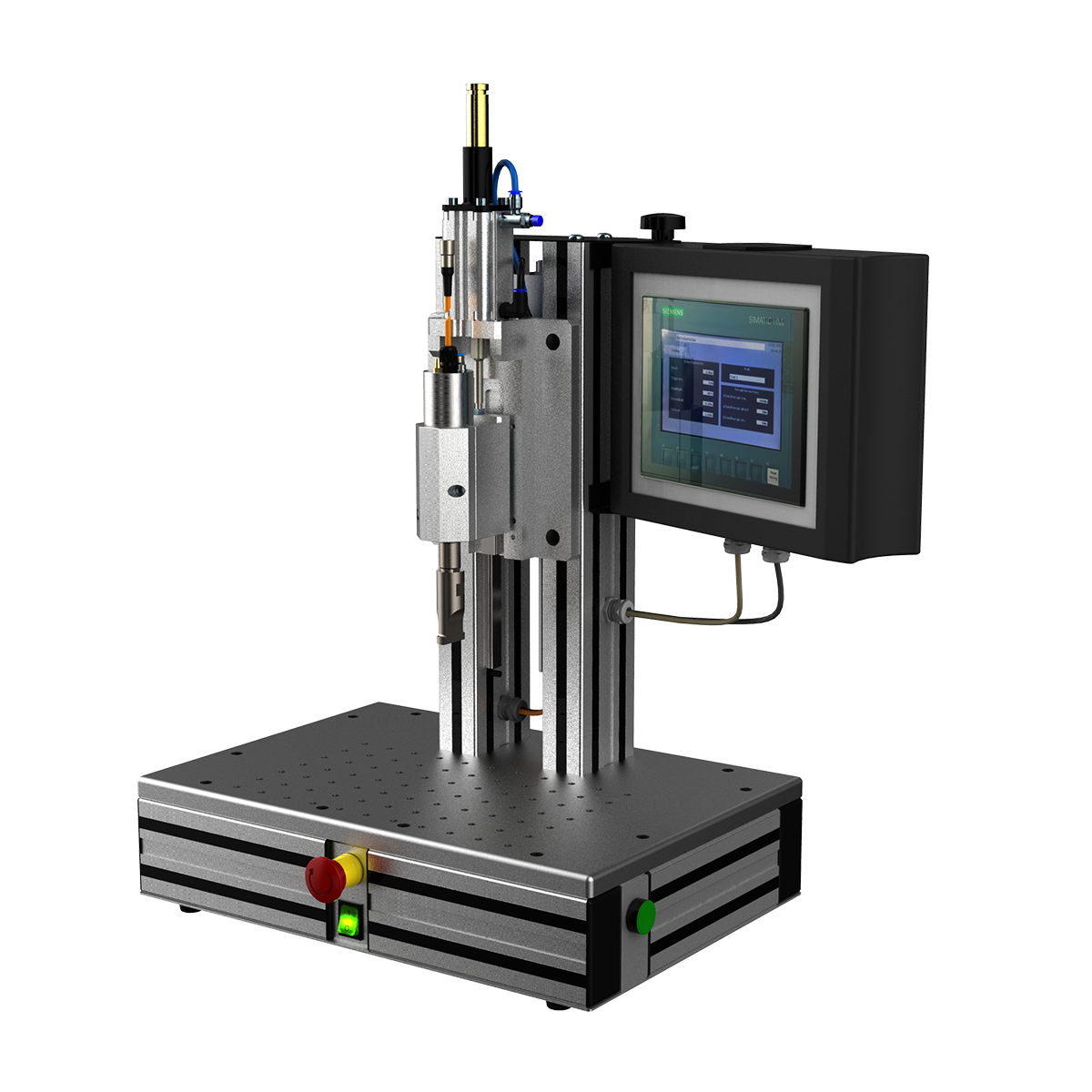

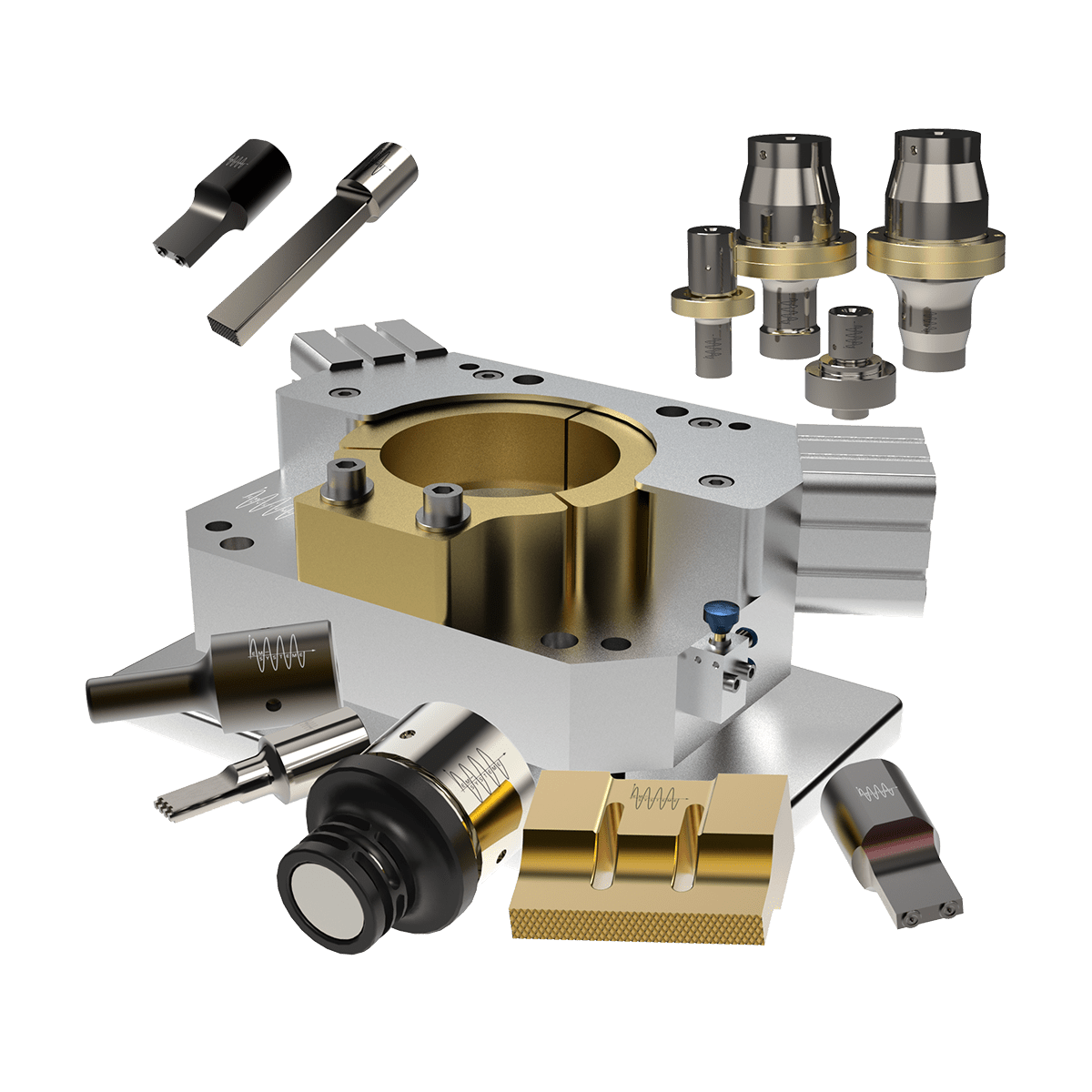

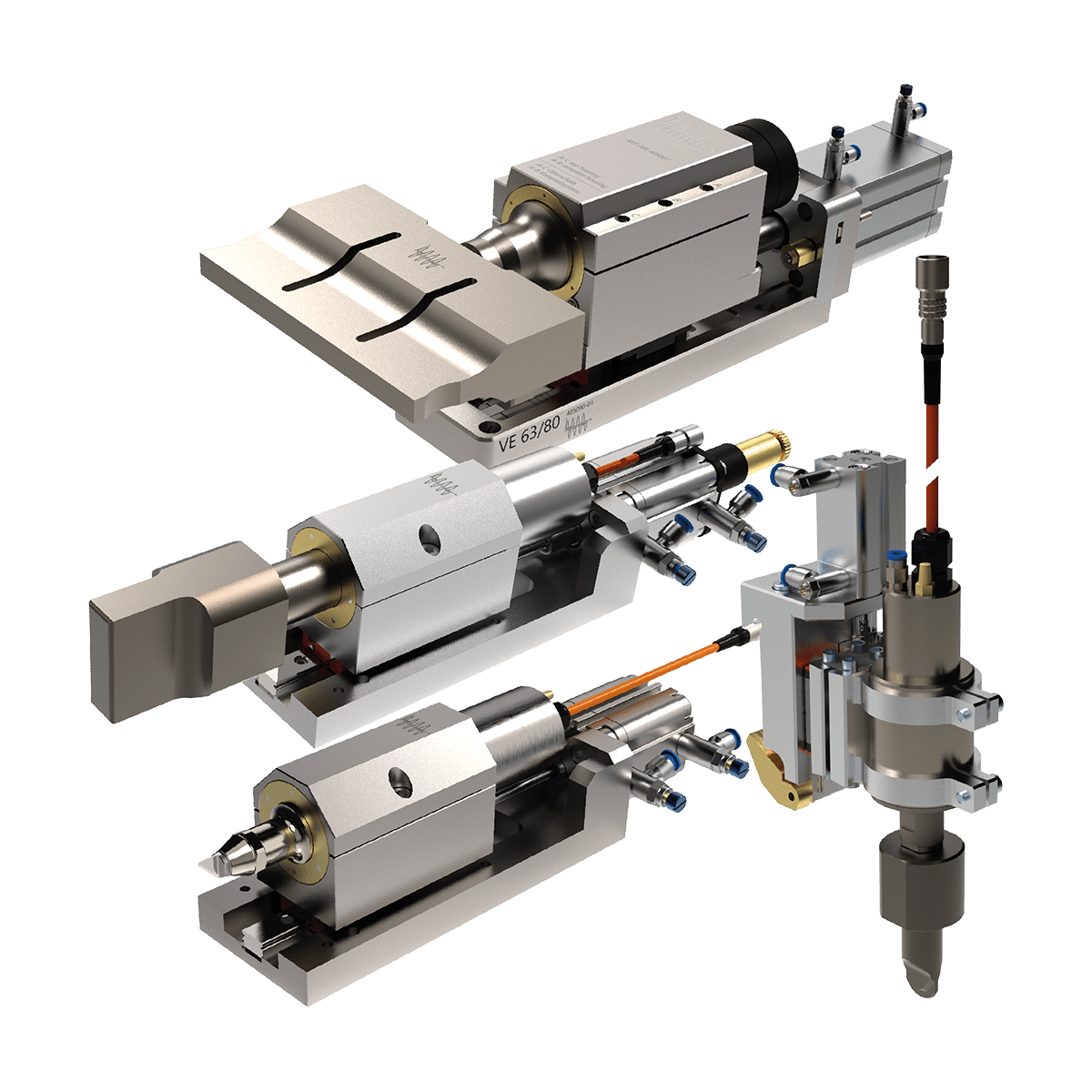

Ultrasonic Sonic Welding

With ultrasonic welding, thermoplastic materials can be joined together or plasticized by frictional energy. Using special tools, the so-called sonotrodes, mechanical vibration is introduced into or onto the component. Depending on the seam and component design, welding, riveting or spot welding takes place within a short cycle time. Welding times of less than a second are the norm. The movement of the friction process is not visible because it takes place in the μm range. Typical amplitudes are between 5 – 40μm and usually oscillate at 20 to 40 kHz. When designing the components to be connected, contact should be made with the ultrasonic manufacturer at an early stage in order to rule out fundamental errors.

Application Solutions on the Topic

Ultrasonic Sonic Weldig