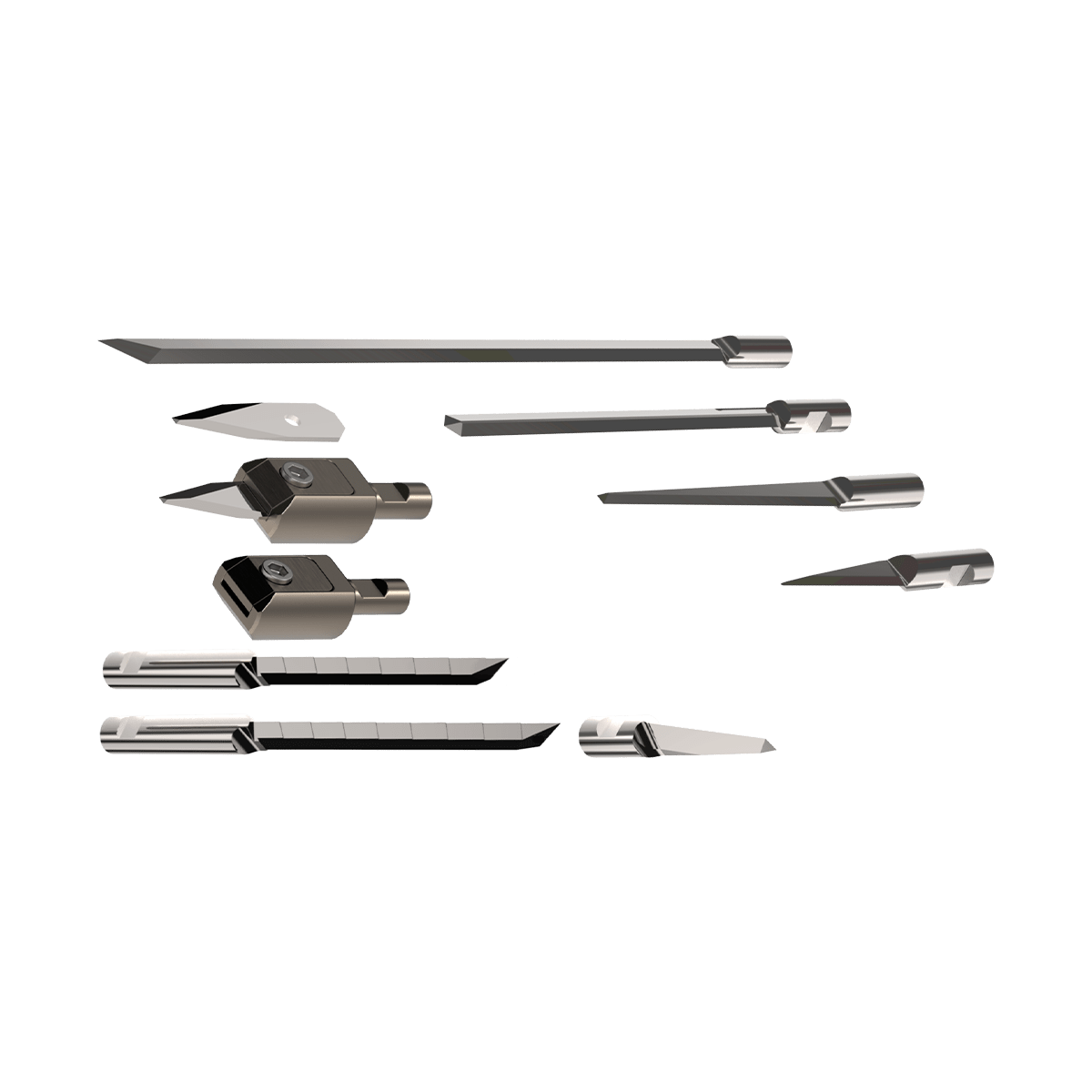

Vibration Cutting

Vibration cutting is as simple as it is effective. Initially conceived as an inexpensive alternative to ultrasonic cutting, vibration cutting has established itself as an important cutting process. Both processes, ultrasonic cutting and vibration cutting, have their ideal areas of application. The small space requirement of the vibration cutting head enables a high level of flexibility during installation and handling. The patented pneumatic resonator of the OS-Cut P150 has a very high performance and rarely finds its limits. With a frequency of approx. 150 Hz and an oscillation range of approx. 7mm, many products can be cut very well. The well-assorted standard range of knives and the possibility of offering customer-specific blades in small quantities complete the program. Send us samples for cutting trials or rent a device to make trials on site.

OS-Cut P150 Cutting Head

The vibration cutting head generates an oscillation in the longitudinal axis with an oscillation path of approx. 7 mm.

Thanks to the frequency of around 150 Hz, very good cutting results can be achieved. Due to the way the vibration head (pneumatic resonator) works, it works very powerfully and highly effectively. The main areas of application are foams, rubber and elastomers, floor coverings, foils, textiles and felt.

Appropriately approved knives can be offered for use in the food sector.