Cut-Off Welding Systems for Continually Applications

Thermoplastic fabrics, knitted fabrics or non-woven materials can be separated very well with ultrasound. Also found under the term “Cut and Seal”, the process is used to separate the material and seal it at the edge at the same time. The textile is plasticized by the ultrasonic vibration and immediately squeezed off. The resulting cut edge is of very high quality because it is soft, there is no smoke or burns and the edge is usually not bulky.

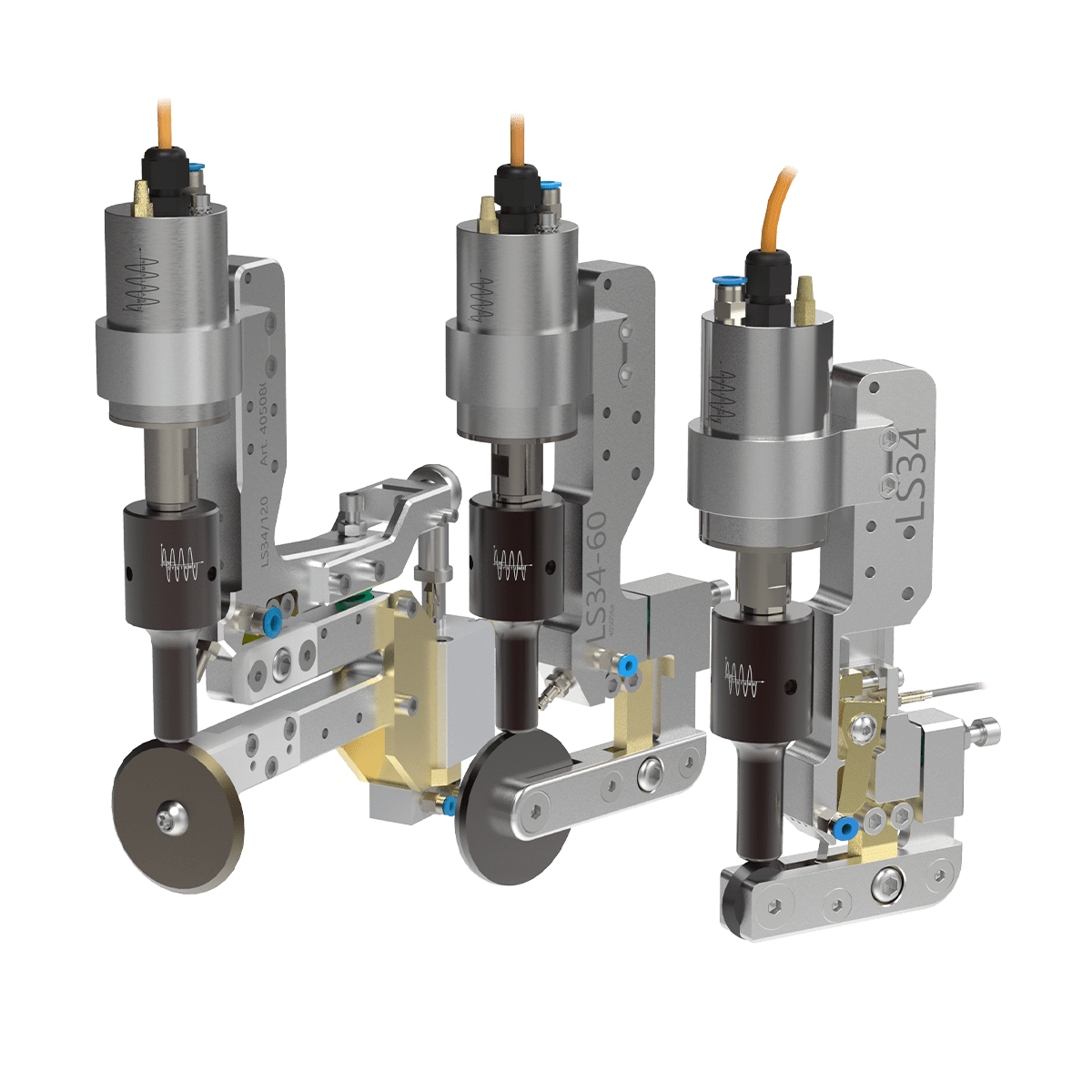

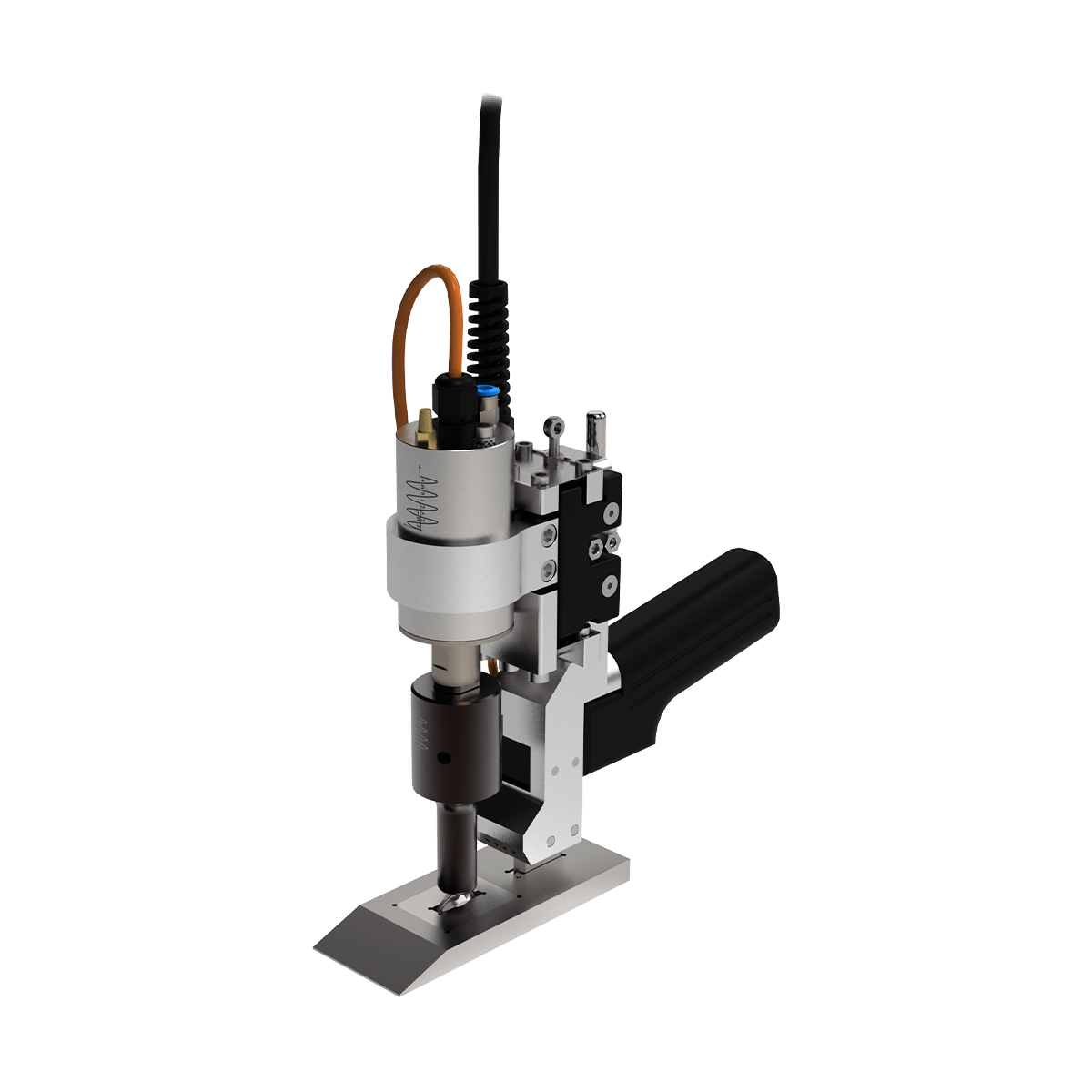

Device Series LS

The ultrasonic cutting units of the LS series have been developed for continuous operation in order to cut web-shaped textiles and at the same time to seal the edge.

The separation welding is also often referred to as cut and seal. A wide variety of designs are available as standard, depending on the application and customer requirements. Let us advise you.

The device can be equipped with 30, 35 or 40 kHz.

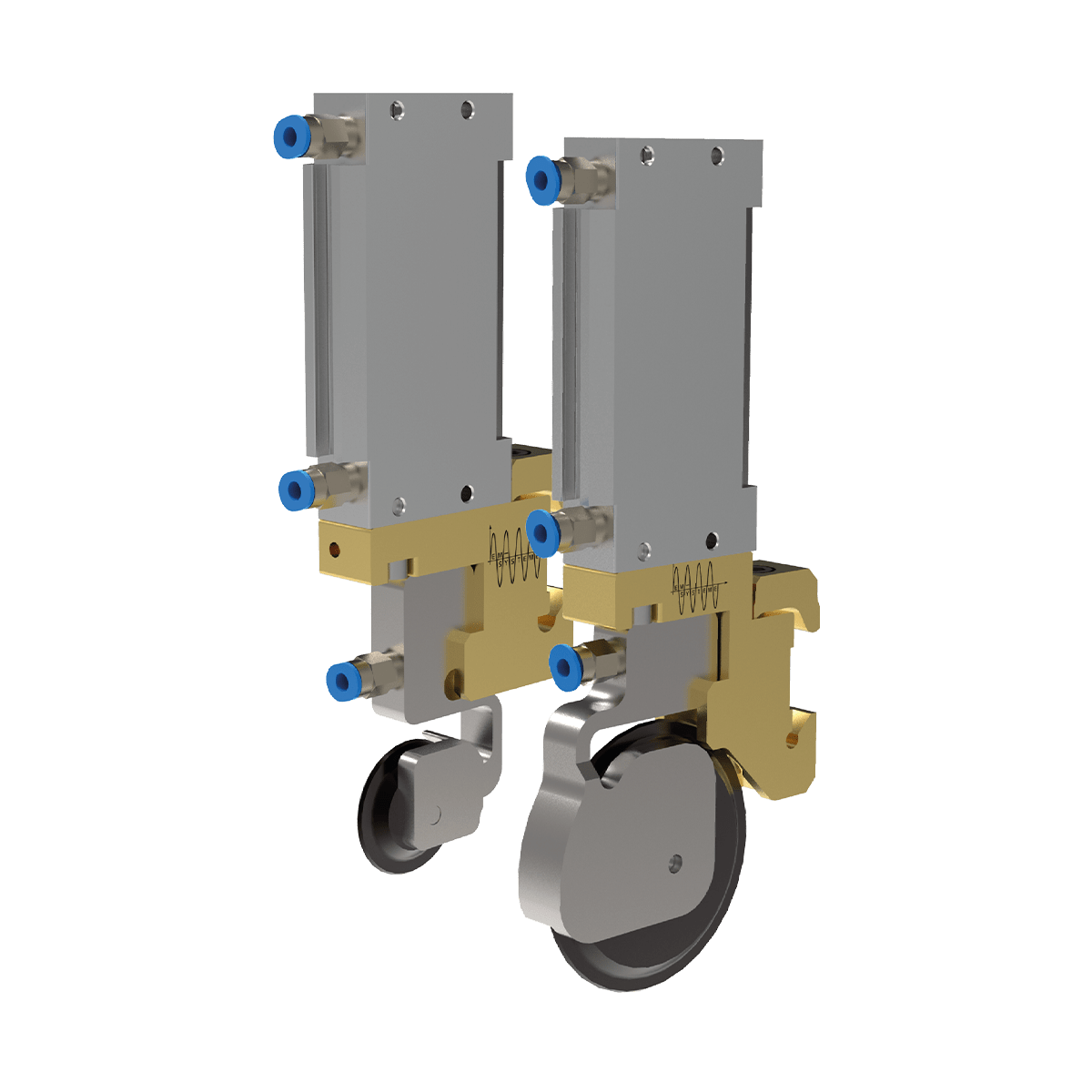

PSH Cutting Units for Narrow Strips

The PSH cutting units are used for narrow belts from 16mm.

In this constellation, several PSH are usually placed on one sonotrode. The special design reduces wear and enables long running times. Another advantage is the flexibility of these units. For the user who has to switch between several fixed widths, there are solutions with fixed-size cassettes or assembly inserts that can also be installed later in order to reduce set-up times to a minimum.

The cutting units are passive and can therefore be operated with all ultrasound systems available on the market, as long as they are basically suitable for applications of this type.

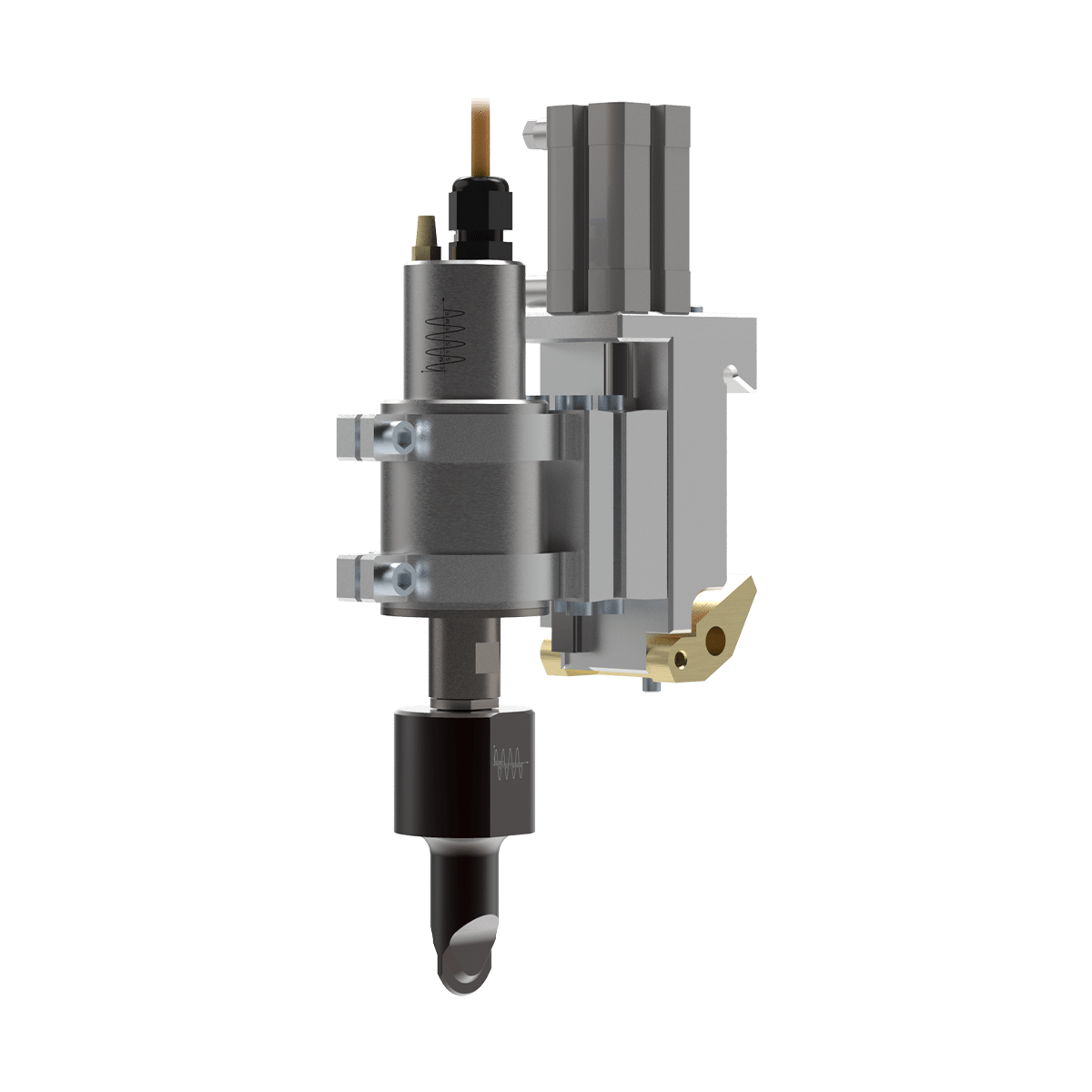

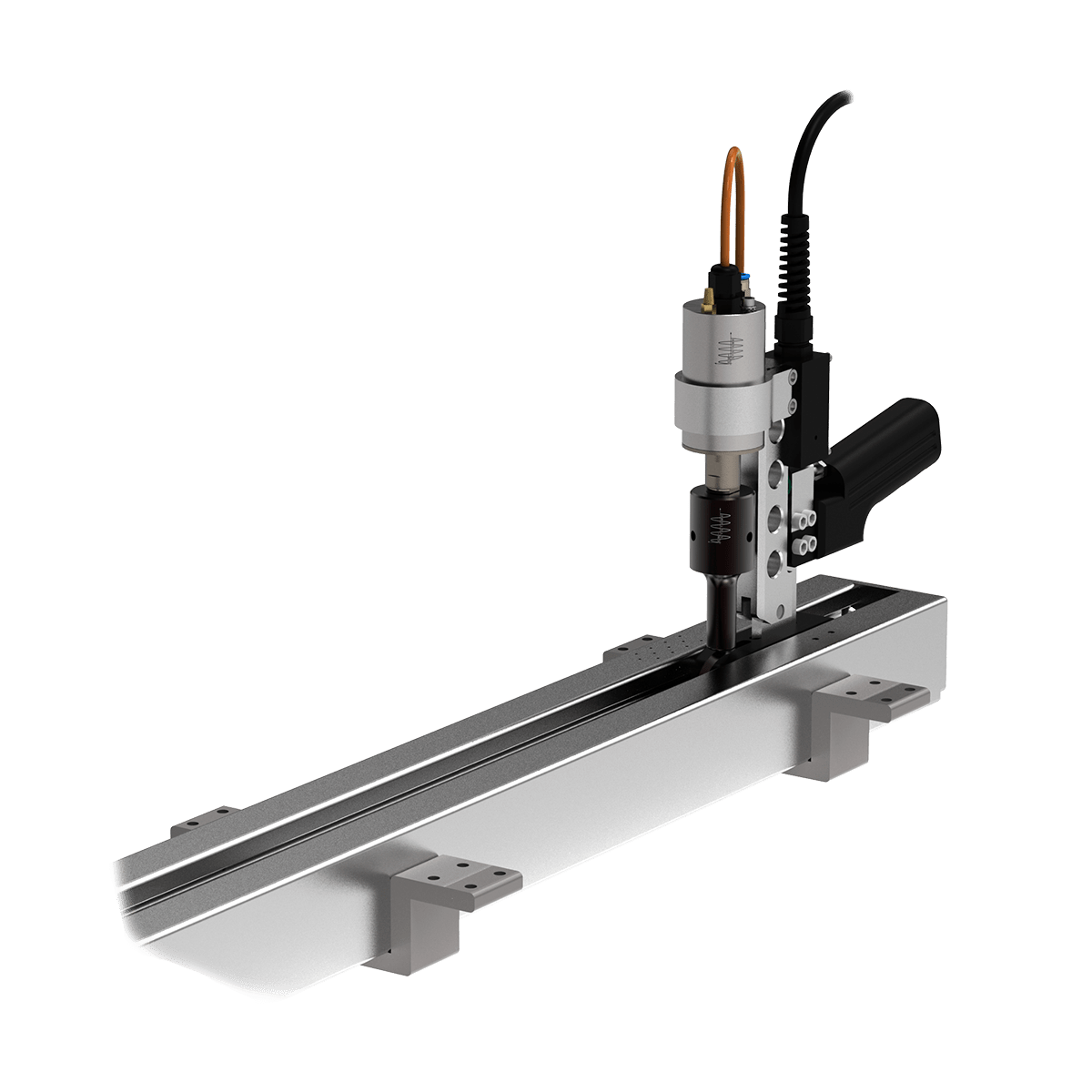

Linerary Manual Cutting System LHS

Modular system based on the fact that the bulky components such as the work table and the guide rails can be bought on site.

This saves high transport costs and makes it very easy to expand at a later date. The basis is a construction that is based on a widespread mechanical engineering profile. You only need special holders to mount the machine construction profile. After assembly, there is a guide rail with support surfaces on which you can assemble your work table. In addition to the ultrasonic unit, you can also use electric scissors in the guide rail if you want to cut textiles from natural fibers, for example.

The device can be equipped with 30, 35 or 40 kHz.