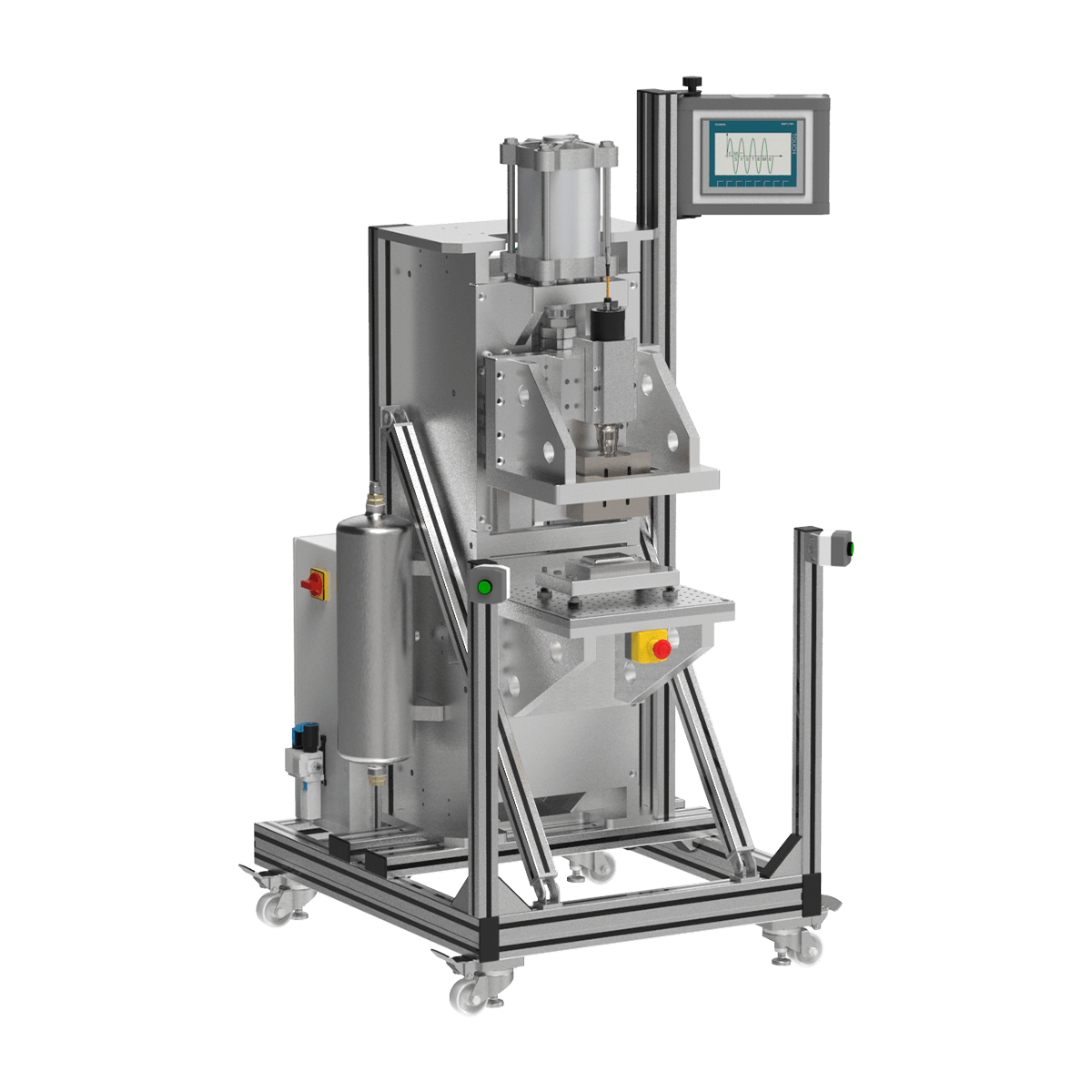

Cut-off Welding Systems for

Intermittent Applications

Typically, belts and bands are the main area of application for the intermittent ultrasonic cut. But wider webs made of microfibre up to a width of 500mm are also separated in one cycle. Shaped parts are cut out on high-precision ultrasonic punches.

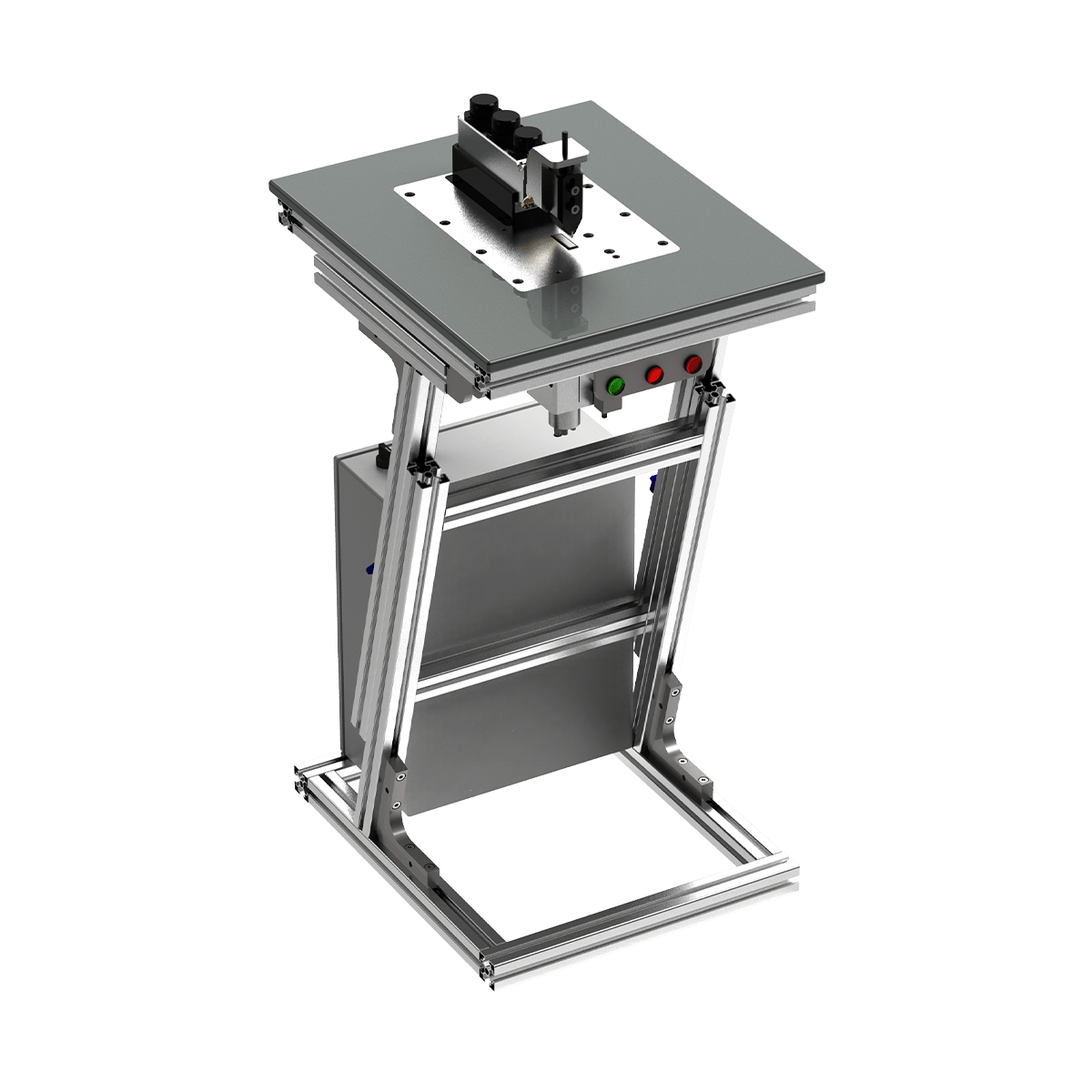

Work Table for Manual Cut-off Welding

This table was originally developed for the cutting welding of ceiling edging tapes.

The simple and flexible operation means that this work table is used in a wide variety of areas. There are almost always applications in which protrusions such as warp seams, unclean corners, label protrusions or just cords or ribbons are manually cut and sealed.