Ultrasonic Blade Cut

Cutting with blades excited by ultrasound has become more and more established in recent years.

Prepreg, tapes, (raw) rubber, floor coverings. Thermoplastic organic sheets, honeycomb, carbon fiber scrims and many other materials have been cut successfully and reliably with our systems for years.

We have been building standard systems since 2002 and have already solved countless applications. Make use of this experience.

With a standard range of now more than 80 different carbide blades for ultrasonic use, we can respond to a wide variety of applications at short notice.

Our Delivery Program includes:

- Blades with steel support in soldered and unsoldered version

- Monoblock blades Ultrasonic disc from Ø15 - Ø70mm

- Carrier sonotrodes (Sonotrans) with and without fixing ring, from

0.5 –2 x lambda - Available cutting heights from 0.7mm to 150mm

- For frequencies of 20, 30, 35 and 40kHz

- Connection thread in all ultrasonic blades available on the market as standard or custom-made

- standardized cutting units

- Rental systems

- Extensive range of accessories and complementary products

- always in a bundle with 25 years of experience

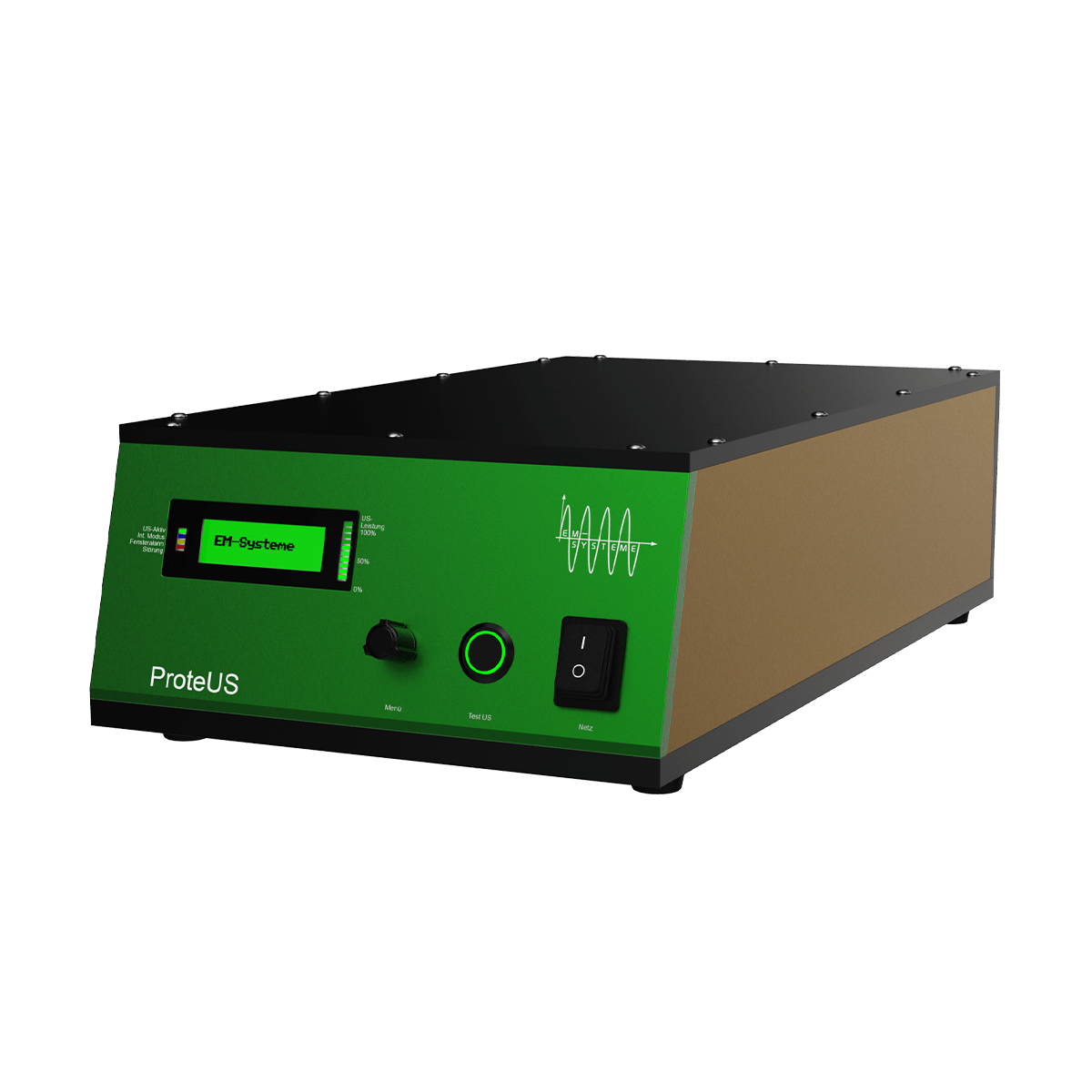

Generators

Different generators can or must be used for different fields of application.

When processing carbon fibers, protected generators must be used to counteract a failure caused by a short circuit. Even externally ventilated control cabinets are usually not safe, as fibers get inside when they are opened.

The ProteUS generator series was specially developed for this purpose.

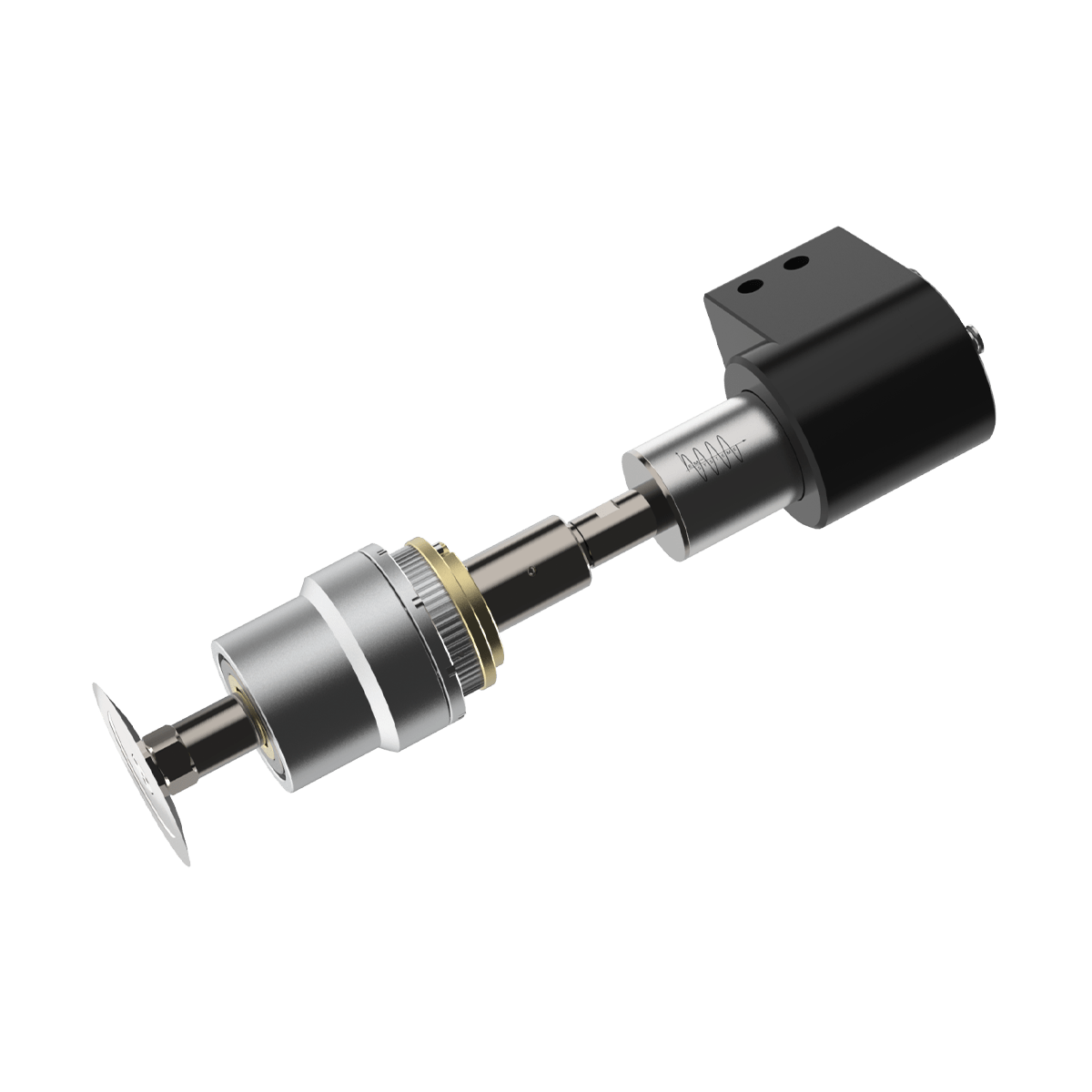

Ultrasonic blades

Our standard range includes over 80 different ultrasonic blades with cutting heights of 0.7 – 150mm, in soldered and unsoldered versions, as monobloc blades in special geometries, also with your connection thread.

More than 70,000 delivered blades in the last 20 years are our reference.

You can find more information under Carbide knives.

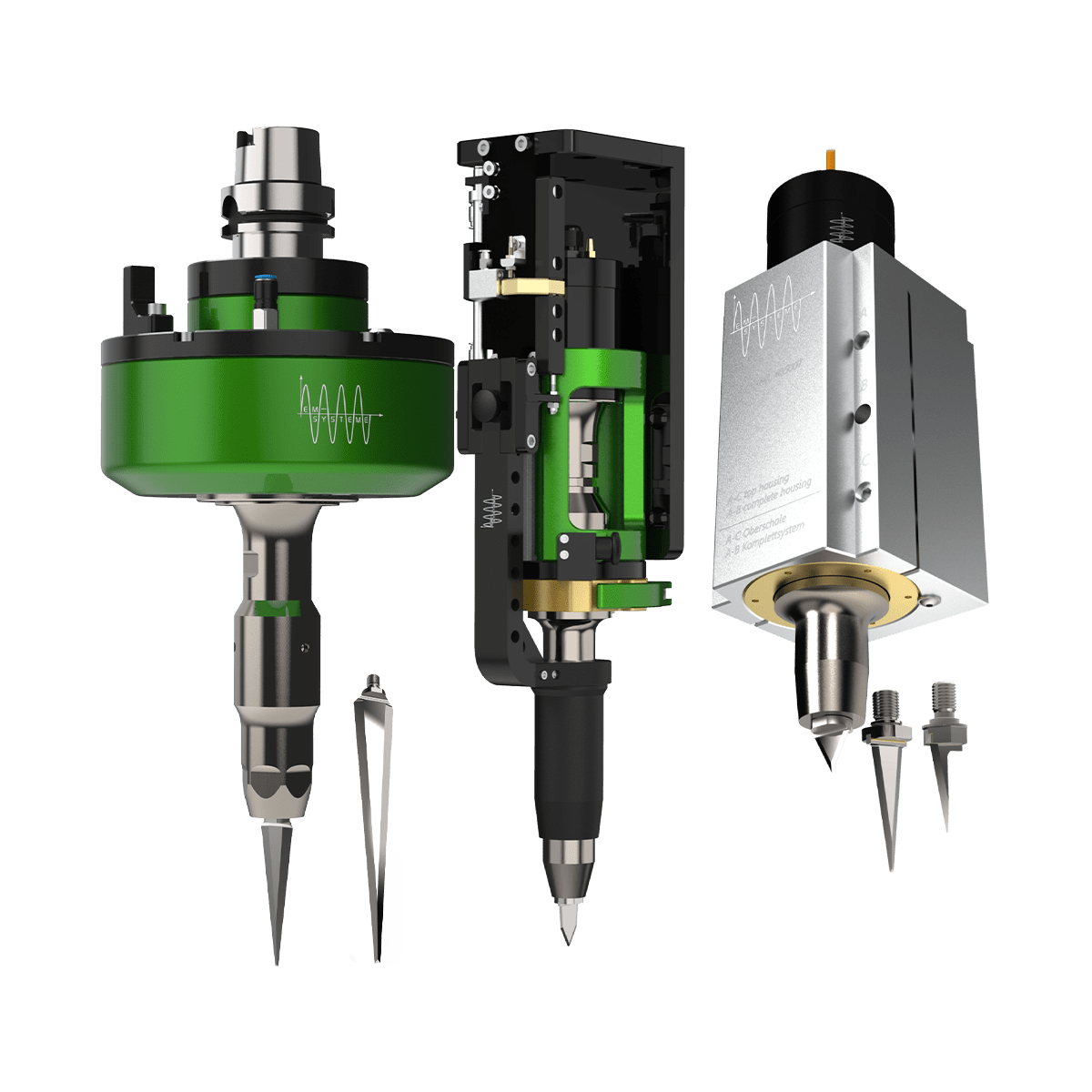

Fastening System

The areas of application for the ultrasonic blades are very diverse and the options for attachment must be just as diverse.

Regardless of whether you work with a hand-held device, cutting plotter, robot, processing system or a stationary system, we almost always have a ready-made solution

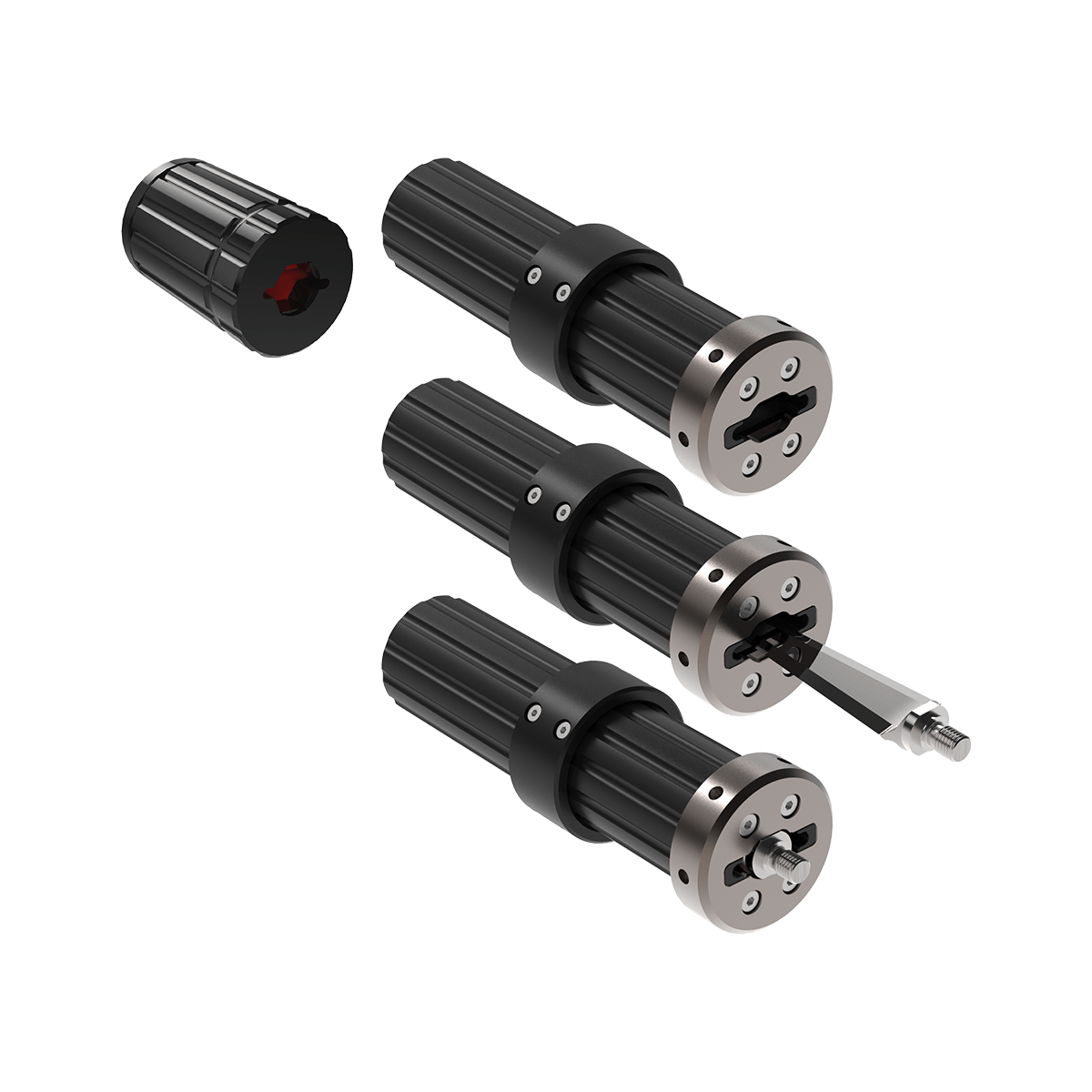

Screw-in and Assembly Tools

The ultrasonic blades are extremely sharp and handling should be done with great care.

For this reason, we have developed special tools that reduce the risk of injury. With the help of the screw-in aid, the already loosened blade can be screwed out or the new blade screwed in. To tighten the screw connection, the screw-in aid is only opened a little to give space for the key and at the same time to keep the blade covered.

The assembly aid is made with a massive approach. In the protected state, the blade can be tightened or opened using a tool.